|

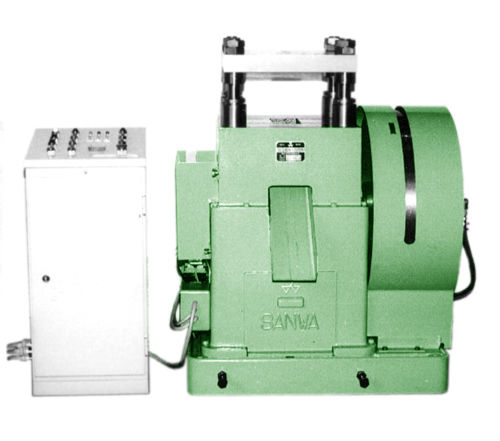

Model: WDM-20H Dieing

Machine

( high speed precision press machine)

This dieing machine is a (rod)

pull-down stroking type with four

highly rigid precision post-guides

and with the motor located at the

bottom of the machine.

The die is located in between the

four precision post-guides to

prevent any effects on the die from

eccentric load, making it an optimal

machine for highly precise pressing

operations.

The machine is low in height and the

accuracy of the machine and bottom

dead-point has passed the highest

JIS (Japanese Industrial Standards)

class of the Japanese Standards

Association (JSA).

The “precision

high

speed

4-post press and pull-down

mechanism” is the main

characteristic of the machine,

preventing any deflection in the

frame (a common problem in

conventional C-frame machines),

allowing it to feed material in a

consistent and accurate manner, and

making it a very versatile machine

suitable for high-speed,

high-precision feeding operations

which also require strict accuracy.

<<

Applications

>>

● High

value-added press-processing of

precision electronic and electric

components which need to be

processed with high accuracy and at

high speeds.

● Being a compact machine, it is

possible to maintain space above and

beside the machine when automating

welding processes in progressive

dies for automatic pressing

operations.

● For cases where conventional press

machines (with motors at the top of

the unit) cannot be used for

automated pressing lines due to

motor oil dripping down from above.

●

Burr-free press-processing of

materials which are particularly

susceptible to burrs and cannot be

processed with standard power-press

machines, like paper.

● Simultaneously press-processing

multiple rows of sticky materials

such as zinc, etc.

● Optimal for press-operations in

between shearing lines.

●

Precision pressing and punching

unbaked, soft and

difficult-to-process electronic

sheets and other ceramic materials.

●

High-precision pressing of film

material.

●

High-precision pressing, stamping

and punching of thin plastic plates

and other plastic materials

●

Press-processing building materials,

including earthquake-resistance

materials.

●

When the product accuracy may be

affected by the eccentric load

during long progressive press

processes.

●

High-speed, high-precision

consecutive piercing of cores for

servo motors and other motors.

●

High-speed, high-precision piercing

of cores for EI transformers.

● High-precision coining, minting

and pressing processes for coins. |

|

|

● |

We accept customer requests

regarding items such as number of

strokes, stroke lengths, shut

heights, punching hole sizes,

processing sizes and bolsters, etc.

|

|

● |

We also accept custom orders

regarding the lengths between the

four posts. |

|

|

型 式 (Model)

|

WDM-20

Dieing Machine

(Press-Machine) |

WDM-40

Dieing Machine

(Press-Machine) |

WDM-60

Dieing Machine

(Press-Machine) |

PDM-80

Dieing Machine

(PressMachine) |

|

20 |

20H |

40 |

40H |

60 |

60H |

80H |

|

Capacity |

ton |

20(200KN) |

40(400KN) |

60(600KN |

80(800KN) |

|

Standard stroke

length |

mm |

30 |

30 |

30 |

30 |

30 |

30 |

40 |

|

Stroke per min (

Standard ) |

SPM |

150 |

125~500 |

150 |

125~500 |

150 |

120~470 |

120~400 |

|

Shut height

length ( Standard ) |

mm |

205 |

205 |

235 |

235 |

235 |

235 |

300 |

Adjust of ram

(Standard)

(Adjust ram length) |

mm |

30 |

30 |

30 |

30 |

30 |

30 |

40 |

|

Open height |

mm |

235 |

235 |

265 |

265 |

265 |

265 |

340 |

Punting hole size

( bed :bolster hole ) |

mm |

200*100 |

200*100 |

350*130 |

350*130 |

350*130 |

350*130 |

400*200 |

|

Motor power |

kw |

1.5 |

2.2 |

2.2 |

3.7 |

3.7 |

5.5 |

15 |

|

Operation |

- |

Continuous,

Single, and Inch-feeding (Jog) |

|

Lubricator |

- |

Automatic

oil-refilling mechanism |

|

Clutch |

- |

Air clutch and

brakes |

|

Footprint |

mm |

1065*913 |

1310*1000 |

1760*1200 |

|

機械寸法 ( machine

figure ) |

mm |

1065*1120*1220(L*W*H) |

1310*1250*1415(L*W*H) |

1760*1510*1650 |

◎ The shut height is the distance

from the top of the bolster to the

bottom of the ram (also

called a “Top plate of the machine”)

with stroke down and adjustment up.

◎ The

open height is the distance from the

top of the bolster to the bottom of

the ram with stroke up and

adjustment up.

◎ For

dieing machines, the upper part of

the frame corresponds to the unit

referred to as a “bolster.”

◎ A

special T-shaped groove bolster can

also be added as an option, only at

order placement of the machine.

|

|

◎The

“H” models refer to

models with continuously

variable transmission

(CVT) specifications.

Models other than

“H-types” are constant

rotating types.

|

|

|

●Dieing

Machine

details and

specifications may be

modified by TOSCOM at

any time without prior

notice. |

|

|

|

Copyright(C)

271008

TOSCOM Co.,Ltd. All rights reserved. |

|